INNOVATION AND DEVELOPMENT

INNOVATION IN PRODUCT DESIGN

Alpinter designs and produces shelter and core relief items exclusively for the humanitarian market. Our products are deployed during the most demanding human and environmental crises, and as such we are continuously innovating to ensure that our products meet the needs of beneficiaries and international aid organisations, both now and into the future.

Our commitment to continuous improvement and innovation starts with our in house R&D and Quality teams. We design, engineer, test and redesign our products, to maximise their utility and lifespan, while minimising their environmental impact. Our quality control and assurance team works directly with our manufacturing facilities to ensure that every Alpinter product deployed to the field is fit for purpose and correctly manufactured, every time.

Our developments over the years

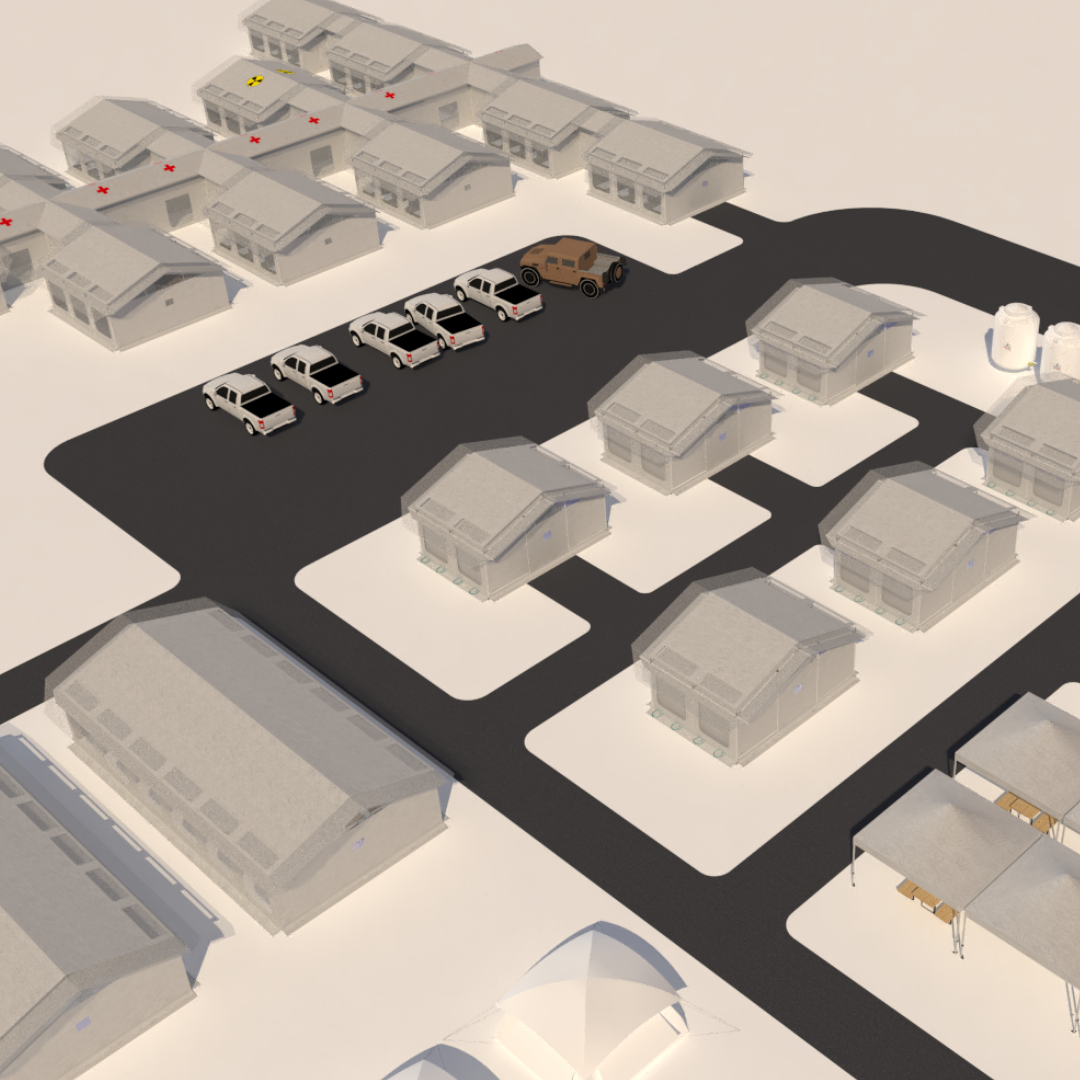

Public - Private Sector Collaboration

The Xpert High Performance Tent was created as the latest generation of Multipurpose Tents, as a collaboration project between UNICEF and industry leaders, including Alpinter. The Xpert High Performance Tent combines additional functionality and a longer lifespan, for greater utility in the feild and a wider range of recycling possibilities.

Alpinter was also instrumental in the design and development of the BLUE (Geodesic) Family Tent, in conjunction with ICRC/IFRC. This model has since been deployed for emergency relief by Red Cross organisations worldwide.

Innovation Helping Sustainability

Our development and innovation process takes into account the overall impact of our manufacturing and logistics activities, across the entire product life cycle. Some examples of our recent efforts in product and logistics optimisations:

- Our jerrycan production facility in the UAE is a zero waste production unit, combining waste material reintegration with innovative applications for the 3,8% of raw material which cannot be used.

- Alpinter-developed the CRI Pallet (an adapted Europallet designed to optimise container loading rates while maintaining compatibility with standard racking systems) and Metal Stackable Pallets for bulky/heavy items such as family tents and shelter tool kits, improve container loading rates by up to 25% and minimising the carbon footprint generated by the transport of goods. Both innovations have since become the standard for international humanitarian organisations.

- Alpinter optimised the packing design for multipurpose tents, to encourage longer lifespan and reuse of the wooden boxes.

In 2020 our environmental efforts evolved and converged into the Alpinter Environmental Impact Initiative, a public statement of our previous and present efforts to minimise our environmental impact, and our commitments to expanding these efforts in the future in conjunction with all industry stakeholders. Download our report here.

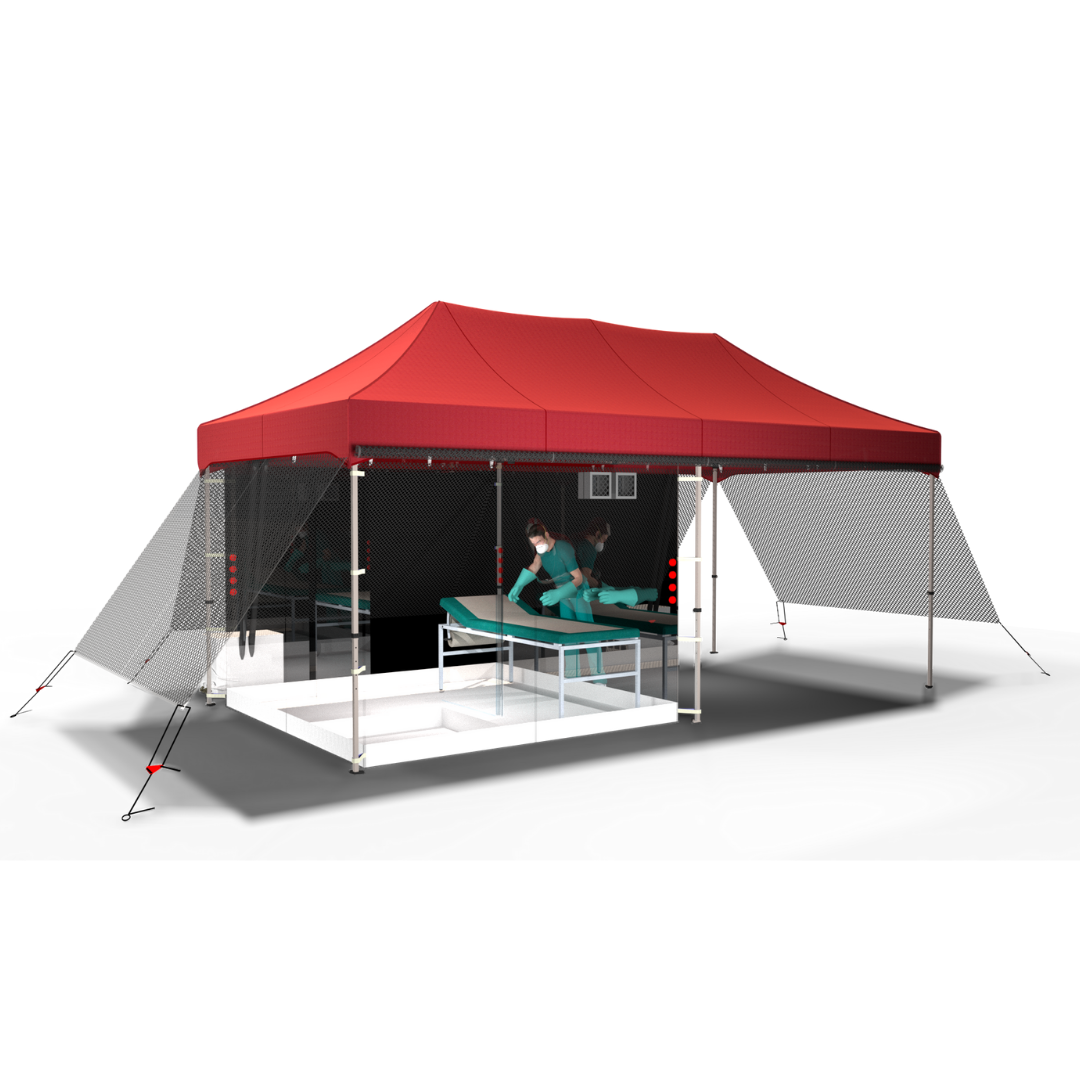

FIRE RETARDANCY: INNOVATION FOR BETTER SAFETY

Innovation and the desire to create safer products has seen us commit to making fire-retardant products. A fire can start anywhere and at any time; an untreated tent will burn to ashes in less than a minute, trapping people inside with very little chance of survival. But when the tent canvas has a flame-retardant treatment or is made from materials like polyethylene (PE) that slow the spread of flames, the probability of combustion is significantly reduced, and offers occupants sufficient time to escape to safety.

Innovation and the desire to create safer products has seen us commit to making fire-retardant products. A fire can start anywhere and at any time; an untreated tent will burn to ashes in less than a minute, trapping people inside with very little chance of survival. But when the tent canvas has a flame-retardant treatment or is made from materials like polyethylene (PE) that slow the spread of flames, the probability of combustion is significantly reduced, and offers occupants sufficient time to escape to safety.

Read more on fire testing of our products and the importance of reducing risks in humanitarian contexts.